If you haven’t joined the craze and purchased your very own Official Creality Ender 3 Pro 3D Printer then read on to get the most out of one!

There are several instructional videos on how to setup your machine. I recommend you watch the following video and check out the videos listed at the bottom of this page:

I have setup three Ender 3 Pro machines and keep two of them going constantly. I’m sharing what I found to be most important and useful when working with this printer.

Foundation

The term “bed leveling” means adjusting the bed so that it is level with the nozzle.

This is important because the first layer in a build is the main support for the rest of the print. In order to achieve a solid base, the bed must be properly oriented to provide the correct adhesion and delivery of the printing material.

If the nozzle is too far from the bed, the filament won’t adhere to the build plate at all. Too close and the nozzle will push past the layer height, preventing the material from extruding and sticking. Either way, the foundation will be unsatisfactory. The sweet spot is when the nozzle allows some space but applies just a little pressure to the flowing filament in order to help it adhere to the build plate.

The Ender 3 doesn’t have an auto-leveling feature, so you have to level the bed manually.

There is an upgrade available using the BLTouch Sensor.

After a few days of trying out the BLTouch, I decided it was more annoying than helpful and removed and returned it. Each print requires that the printer check all 9 sections of the bed before printing. If you have a bed that is not flat, has some wave in it, then this will be helpful for getting good prints.

Manual leveling is necessary even if you do have the BLTouch installed. Fortunately, this isn’t too difficult and is aided by some of the printer’s features. The menu provides actions that prepare the device for leveling, and the four large knobs under each corner of the bed make the job easy.

You’ll find that, once leveled, the bed will stay that way for some time. Periodic re-leveling may be necessary but once the procedure is learned it should take less than five minutes to re-level each time. I found that one or two of my adjustments felt sloppy as though there wasn’t sufficient tension…

I recommend upgrading the bed-leveling springs installed above the adjustment knobs with silicone spacers. I used these for my printers: 3D Printer Leveling Parts, Heat Bed Silicone Leveling but I think these are more specific to the Ender 3: 3D Printer Heatbed Parts, Solid Bed Mounts, OD 0.63 in ID 0.16 in Stable Hotbed Tool Heat-Resistant

Software

You can use the Ultimaker Cura Software included and recommended by Creality. Download and install the latest version which will contain the latest default profile settings. Most 3D prints can use the default settings for the Ender 3 Pro. Other then bed-leveling, the area that I have found to require some tweaking, depending on the time of year, and whether or not you have an enclosure for your machine, is the temperature. This Winter I have been printing PLA at 210c.

Plate and Nozzle

Before starting to level the Ender 3’s bed, there are a few things you should do to get the machine ready:

- Make sure the build plate is clean. On the Ender 3, you can remove the build plate and clean it.

- Clean off anything that is sticking to the surface. Use a spatula if needed to break off loose material.

- Wash the build plate with warm, soapy water, and dry it with a clean cloth. Make sure no lint or particles remain.

- Reattach the build plate to the heated bed using the clips. Check carefully to ensure that the entire build plate is flat with no ripples or high spots.

- Ensure that the nozzle is clean and free of material. It shouldn’t have any plastic protruding from the tip. An easy way to do this is to heat up the nozzle to the temperature last used and gently wipe off the tip with a soft cloth. If you do this, wear a glove so that you don’t touch the hot nozzle with your fingers.

Tune the Machine

To prepare for leveling you have to position the nozzle and bed. The Ender 3 controls make this easy.

- Turn on the machine.

- Press the control knob and scroll to the PREPARE menu.

- Scroll down to AUTO HOME and press the knob. The hot end will move to the left front of the bed and stop.

- Once again go to PREPARE.

- Scroll to DISABLE STEPPERS and press the control. This will make it easy to move the bed back and forth.

- Next, rotate each of the four leveling wheels counter-clockwise to lower the bed. One or two turns each should be sufficient. The purpose of this is to make sure that the bed is lower than the nozzle tip.

Level the Bed to the Nozzle

I suggest you make your bed adjustments once while the machine is off and/or cold. Then, once again, when the bed and nozzle are heated. The only tool you need to level your bed is a piece of printer paper. Once equipped, you’re ready to go:

- Move the nozzle so that it’s positioned over the left corner of the bed. A half inch or so from both sides is a good location.

- Slide the paper between the nozzle and the bed. If it doesn’t fit, drop the corner until it does.

- Once the paper is able to slide under the nozzle, very slowly raise the corner with the adjuster. Remember: Clockwise moves the bed up. As you do this, gently slide the paper back and forth. The moment you feel even the slightest resistance to your moving the paper, stop turning the knob. That corner is (almost) ready to go.

- Do the same for the other three corners of the build plate. Always advance the hot end to a new corner slowly. This will prevent damage to the build plate in case the nozzle starts to drag. If this occurs, simply lower the next corner (before starting the leveling process) to make some room.

- After you’ve adjusted each corner once, go back and check the four corners again. You may have to do further adjustments to get all four correct.

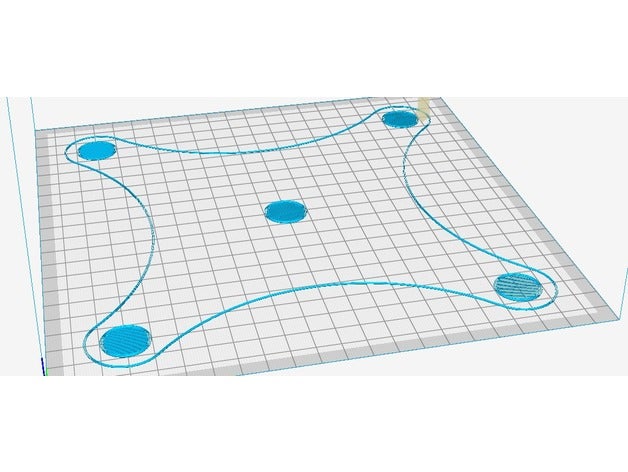

Use the gcode file available through Thingiverse to make the bed-leveling process easier. The bed and nozzle will heat-up and then the nozzle will auto home, then move to the first position to be checked and adjusted if necessary.

Use the gcode file available through Thingiverse to make the bed-leveling process easier. The bed and nozzle will heat-up and then the nozzle will auto home, then move to the first position to be checked and adjusted if necessary.

Download the gcode from Thingiverse that will do this for you!

Printable Upgrades:

Download these printable upgrades from Thingiverse:

- Wire / Cable Clips

- Filament Guide

- Z-Axis Stepper Motor Spacers

- LCD Display Back Cover

Additional Upgrades:

After many hours of use it will become necessary to replace the bowden tube that directs the filament to the nozzle. Authentic Capricorn PTFE Bowden Tubing and go all metal with this nice upgrade Upgraded Creality Ender 3 All Metal MK-8 Extruder Feeder Drive

Additional Video Resources:

Chuck explains how to get started with 3D printing using an Ender3. He explains where 3D designs come from. How you convert a design to a printable file.

Teaching Tech is a YouTube channel dedicated to providing quality content that will help expand your technology related skills and knowledge.

1 Comment